Degradable plastics from waste products

A team of researchers in macromolecular chemistry at the University of Bayreuth is showing how building blocks from sulphur waste can be combined to create new sustainable polymers.

Elemental sulphur, a waste product of crude oil refining, represents a promising possibility for the synthesis of degradable materials, i.e. the combination of elements to form new substances. In a recent article published in the journal Angewandte Chemie, Prof. Dr Alex Plajer, Junior Professor of Macromolecular Chemistry, and his team show that incompatible building blocks can be combined for the utilisation of sulphur waste.

The purpose of this research is to develop new and sustainable polymers. Industrial waste products are to be utilised for this purpose, in this case sulphur, which is produced during the refining of crude oil. The new type of building block combination developed by the Bayreuth team of scientists makes it possible to combine simple sulphur with propylene oxide, a building block already frequently used in industry. Previously, this was not possible because they were not compatible. This could provide access to new materials that have the thermal and mechanical properties of standard plastics but are also degradable.

Developing a detailed understanding of new plastics and their functions while at the same time reusing sulphur waste is the idea behind the research of Prof Dr Alex Plajer and Cesare Gallizioli. "Sulfur waste is produced in large quantities during oil refining," explains Prof. Dr Alex Plajer, Junior Professor of Macromolecular Chemistry at the University of Bayreuth. "We have now reacted this sulphur in our research in such a way that new plastics are created."

The new reaction method produces materials that consist of long chains. "But there is also the possibility of simply linking these chains together," says Plajer. "These not only remain degradable, but also have special properties, such as the fact that they refract light well.

"In our article, we show how, by precisely understanding the processes, you can combine different substances that don't normally go well together to utilise waste sulphur in a meaningful way," says Plajer. "In short, how we can partner building blocks already commonly used in industry to create a new plastic that is easier to recycle."

The research was carried out jointly with Dr Peter Deglmann, BASF SE, and Prof Dr Helmut Schlaad, Professor of Polymer Chemistry at the University of Potsdam. It was supported by the Chemical Industry Fund of the German Chemical Industry Association.

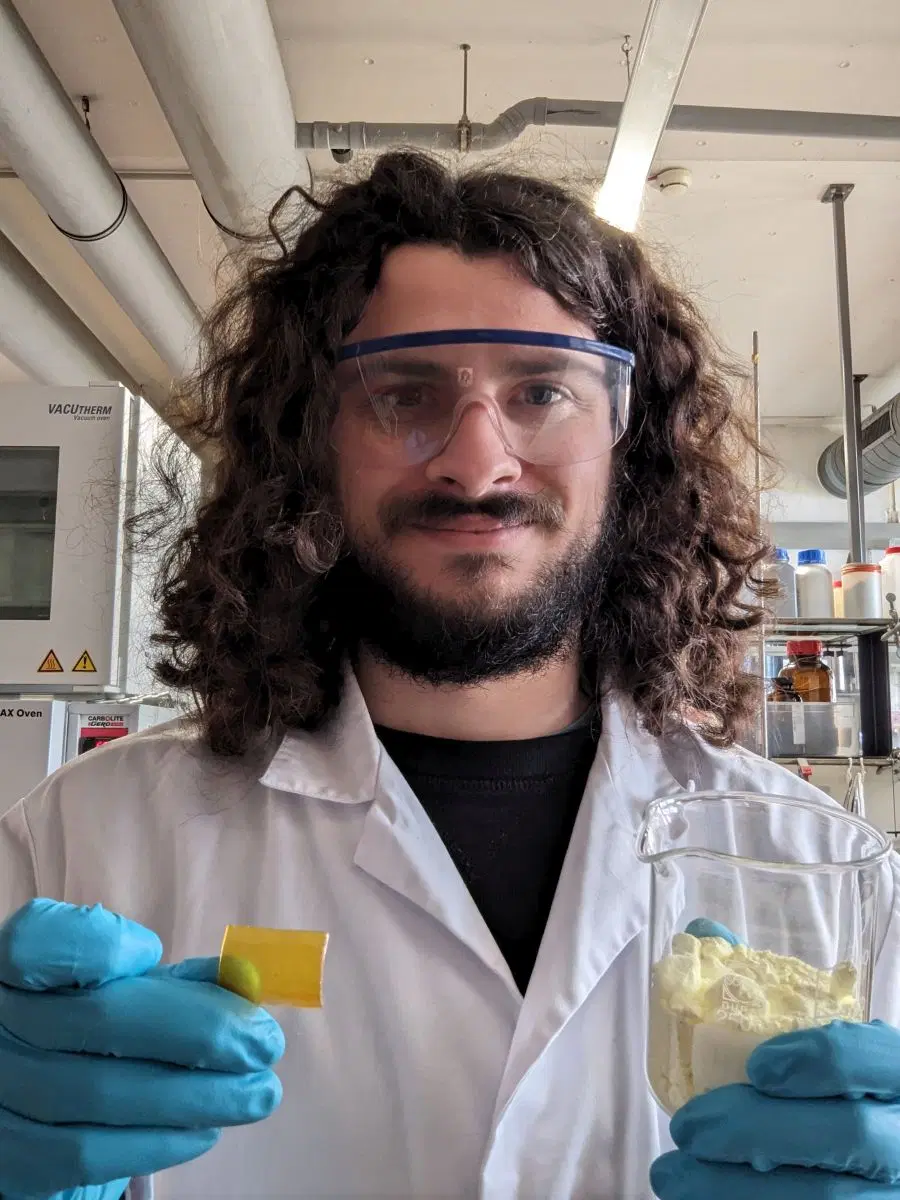

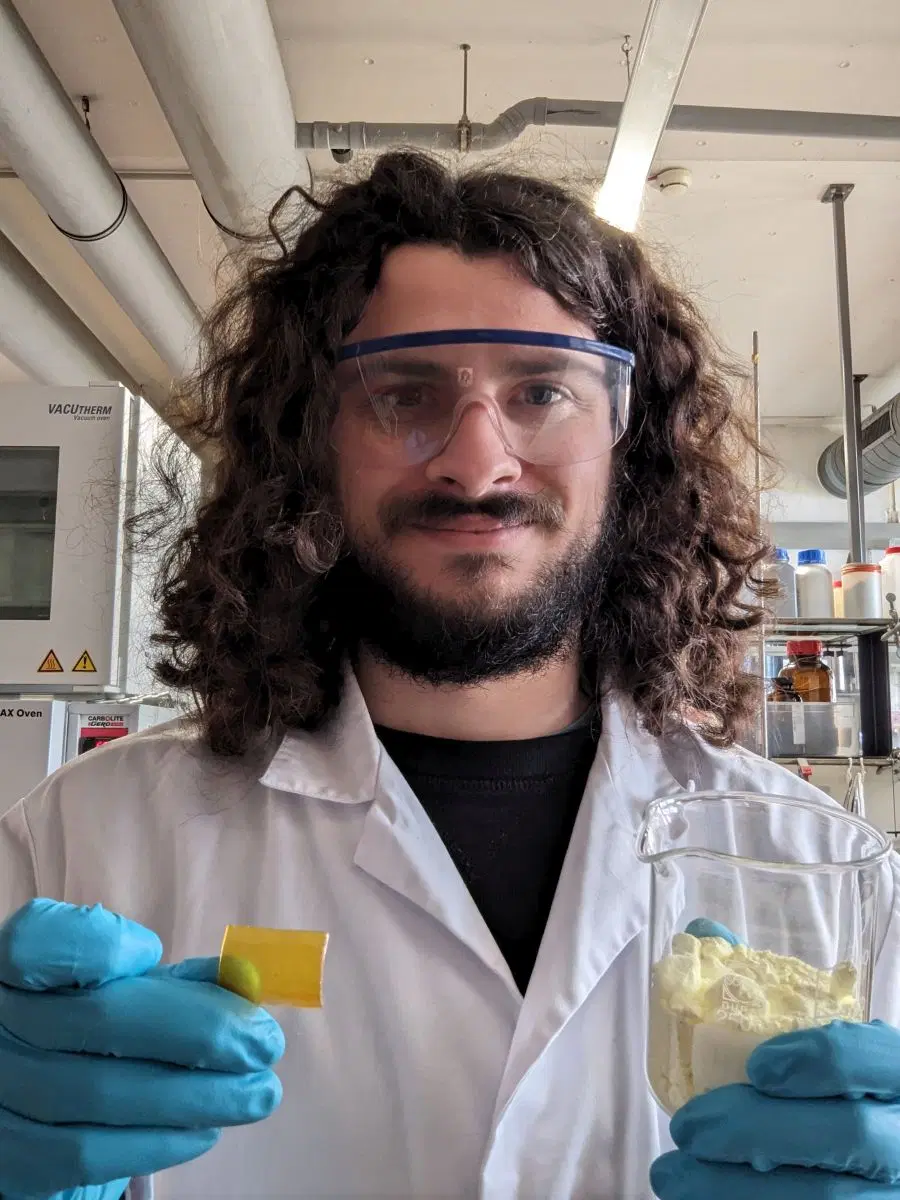

© University of Bayreuth | Cesare Gallizioli, doctoral student under Prof Dr Alex Plajer, shows the sulphur used in the Bayreuth laboratory.