Manufacturing technologies for low-cost and safe aluminium-ion batteries

A cheap and safe alternative for lithium batteries.

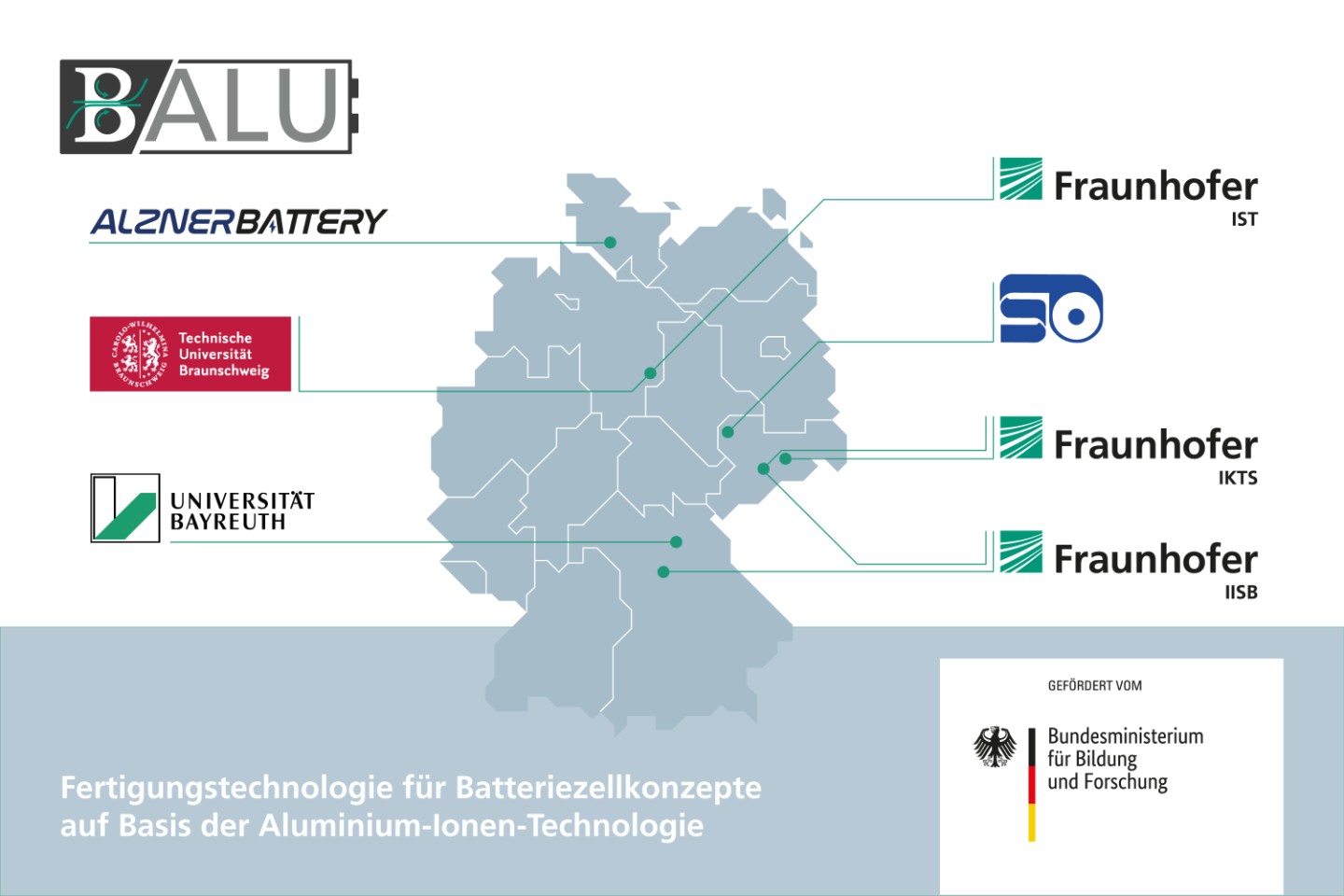

The Fraunhofer Institute for Integrated Systems and Device Technology IISB and the Chair of Systems Engineering for Electrical Energy Storage (SysEE) at the University of Bayreuth are among those working on the BALU consortium project.

In the joint project "BALU - Production technology for battery cell concepts based on aluminium-ion technology", a consortium of research institutions and specialised industrial companies is further developing the aluminium-graphite dual-ion battery (AGDIB). Due to its high power density, AGDIB technology has great potential in the area of highly dynamic load requirements and could be an alternative to cost- and material-intensive lithium batteries. The project pursues the ambitious goal of transferring the production of AGDIB cells from laboratory scale to industry-compatible production conditions. In addition to the transfer of the new battery technology, ecological considerations, such as the avoidance of critical raw materials, environmentally friendly production or subsequent recycling, play an explicit role. The BALU project is funded by the Federal Ministry of Education and Research (BMBF) as part of the "Batterie2020Transfer" programme.

Too good to be true?

It would be a technological breakthrough: inexpensive, powerful, rechargeable batteries, without critical raw materials or flammable materials, easy to manufacture, safe to operate and easy to recycle after years of use.

A new technology with the somewhat unwieldy name "aluminium-graphite dual-ion battery", AGDIB for short, could actually make this possible. Prototypes already exist in the laboratories of the Fraunhofer THM in Freiberg, which have demonstrated the potential of the cell chemistry in extensive test series. With its high power density, AGDIB would be particularly suitable for highly dynamic load requirements, where the cost-intensive lithium titanium oxide (LTO) technology has so far been the state of the art.

The decisive factor for such applications is the highest possible charging rate. The higher the charge rate, the faster the cells can be charged and discharged. Tests with flexible AGDIB pouch cells have shown that long-term stable operation is possible at very high rates of over 30 C, a very good value for this cell format. The other electrical parameters and cycle stability can also keep up with the performance of expensive LTO batteries. In contrast to LTO technology, however, AGDIB uses non-toxic, inexpensive and readily available materials.

Out of the lab!

However, the design of the laboratory samples is not yet suitable for series production, and completely new development tasks will have to be tackled before they can be transferred to mass production. This concerns both the production of the materials used and the individual cell components as well as the design and production of the entire AGDIB cell.

Motivated by the promising test results, a consortium of research institutions and specialised industrial companies has now come together to take the next decisive steps towards market maturity. Under the umbrella of the BMBF joint project "BALU - Production technology for battery cell concepts based on aluminium-ion technology", partners from various specialist areas are contributing their expertise and jointly driving forward the development of the AGDIB.

As the name of the project suggests, the ambitious goal is to transfer the production of AGDIB cells from laboratory scale to industry-compatible production conditions. Economical roll-to-roll processes are coming to the fore in order to produce large quantities of multilayer pouch cells.

As soon as the AGDIB pouch cells are available in sufficient quantities, the project partners can build complete battery modules, specify the operating behaviour of the cells and define the parameters for the system design. The AGDIB high-performance modules are then integrated into industrial battery systems and have to prove their quality in practical operation. The focus here is on specific applications, such as electrical power boosters for large appliances or stationary storage systems for power grid stabilisation.

Thinking batteries further

Not only electrical performance and production technology play a role in the further development of the AGDIB, but also economic and ecological considerations. The global demand for electrical energy storage systems is constantly increasing and the ongoing electrification requires more and more resources. With the increasing use of batteries, questions about the materials used, environmentally friendly production and operational safety as well as subsequent recycling are becoming more important.

All of this must be taken into account at the earliest possible stage of technology development. The BALU consortium brings together broad expertise in the fields of materials research, production technology, battery system technology and life cycle assessment. In addition to possibilities for substituting critical raw materials, the project partners are analysing all steps from cell and module design to system integration with regard to their recycling-friendly design and are looking at the entire product life cycle from a holistic perspective.

The search for alternative material systems is particularly worthwhile with regard to the cost-intensive LTO battery cells. For highly dynamic applications, it is not primarily the energy content of a battery that is important, but the fastest possible provision of electrical power. This is where the aluminium-graphite dual-ion battery has great potential. It combines economic advantages and environmental aspects.

© Jürgen Lösel / Fraunhofer IISB | Technology development in the field of electrode coating for aluminum-ion battery cells in the BALU consortium project.

© Elisabeth Iglhaut / Fraunhofer IISB

© Thomas Richter / Fraunhofer IISB | In the BALU joint project, seven partners from research and industry are further developing the technology of the aluminum-graphite dual-ion battery (AGDIB).